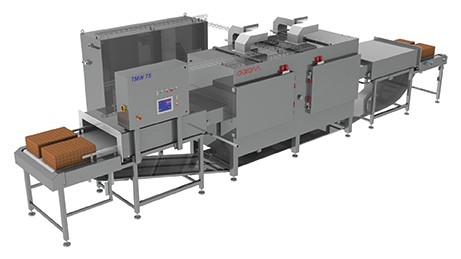

SAIREM, a world-leading specialist in microwave (MW) and radio frequency (RF) industrial solutions, will showcase the company’s innovative food industry processes at Anuga FoodTec from 19th-22nd March 2024 in Cologne, Germany. On display at the SAIREM booth will be one of the company’s tempering tunnels as well as samples of treated products.

Energy-efficient solutions from the food-safety experts

SAIREM, located in Lyon, France, is an expert in MW and RF solutions for a wide range of industries and applications in the food sector. For over 40 years the company has developed customized and highly specialized equipment and processes and has excelled at ensuring food safety and process efficiency. SAIREM’s tailored food solutions lead to products that are healthy, of consistent high quality and have a long shelf life.

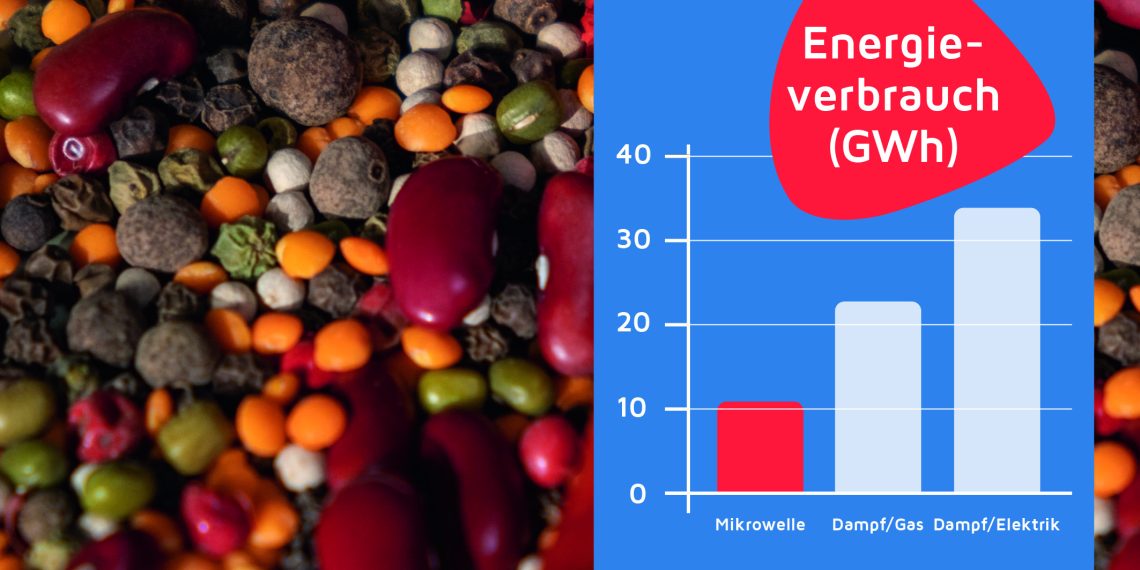

Sylvain Tissier, Business Development Manager at SAIREM, adds, “Our solutions are fully electric and highly energy efficient. In addition, they are easy to install and easy to maintain, offering maximum reliability with few moving parts.”

Tempering and defrosting – safety and speed go hand in hand

The speed and uniformity of SAIREM MW and RF processes minimizes product drip losses as well as degradation. The entire product is tempered quickly and homogeneously which ensures that bacteria don’t have time to grow. These processes are ideal for meat, fish, seafood, fruit and vegetables, and butter. Product color, weight, taste, and vitamins are fully retained. Customers gain flexibility as there is no need to unpack ingredients – they can be processed inside the plastic film, cardboard, or plastic box. To experience the significant advantages of a SAIREM tempering tunnel, visit the company booth at Anuga FoodTec.

Pasteurization – enhancing taste, quality, and shelf life

SAIREM equipment for MW pasteurization includes tunnels for ready meals and in-line heaters for pumpable products such as juices and jams. Thanks to the fast and uniform heating process, a substantial reduction in the microbial load is rapidly achieved both at the core and the surface of the food. Consumers are demanding safer and healthier products that preserve taste and goodness while eliminating the use of preservatives or additives, especially when it comes to ready meals. MW pasteurization delivers all these advantages.

Disinfestation and decontamination – food safety at its most efficient

SAIREM offers a highly efficient process for the disinfestation and decontamination of low water content products such as flour, cereals, spices, grains, lentils, beans, mushrooms, cocoa beans, nuts, seeds, cannabis, and milk powder. The process destroys mold, bacteria, larvae, and other insect colonies without the use of controversial chemical products. By exposing the product to a MW or RF frequency field within a temperature-controlled processing cavity, the product is quickly and uniformly brought to the required temperature, thus preventing alteration of its physical, chemical, and organoleptic characteristics.

Extraction – preserving flavors and fragrances

When it comes to laboratory-scale compound extraction from plants for the food or fragrance industries, preservation of the organoleptic as well as the physical-chemical properties of an aroma is essential. Using traditional technologies, customers face low yields and unwanted components. By using microwaves, SAIREM achieves higher yields, reduces the processing duration dramatically, and reduces or even avoids the use of solvents. Furthermore, SAIREM has developed a continuous microwave-assisted extraction process to serve the needs of industrial production, a breakthrough that opens new avenues in fast and efficient MW-assisted extraction.

Future-oriented technology and comprehensive solutions

Future-oriented technology and comprehensive solutions

By harnessing the power and strength of MW and RF, SAIREM offers state-of-the-art solutions tailored to the needs of a wide range of food industry sectors. SAIREM solutions cover all angles: proof of operation and extensive testing is performed at the SAIREM lab; development engineers support customers during the design phase; equipment design and assembly is provided, and a factory acceptance test as well as installation and start up at customers’ facilities is carried out. To round off its comprehensive customer service, SAIREM trains customer technicians and offers maintenance performed by a multilingual customer service team.

Sylvain Tissier adds: “At SAIREM we develop high-performing machines with advanced technology specially adapted to customer requirements. For companies who are interested in the many possibilities of our innovative systems, we will be available at Anuga FoodTec in Cologne.”

Visit SAIREM at Anuga FoodTec:

Hall 6.1 Booth B071

19th-22nd March 2024