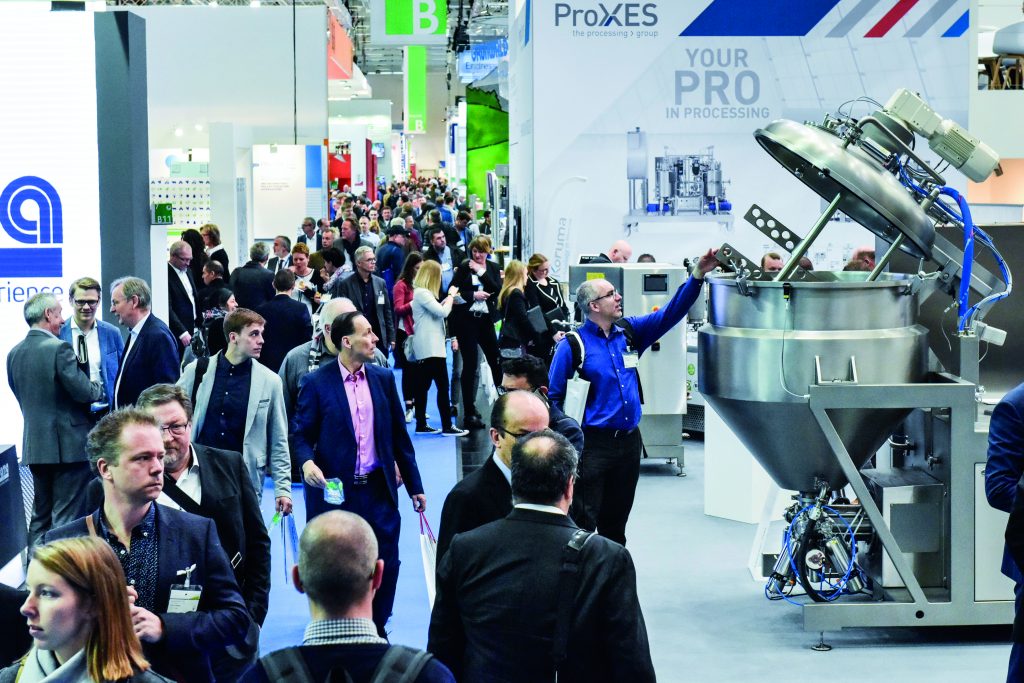

How can the safety of food be guaranteed in the context of international chain stores and the at the same time growing need for transparency regarding the origin and processing? This question is one of the key themes at Anuga FoodTec, which is being staged in Cologne from 26 to 29 April 2022. To minimise the consumer protection risks and guarantee the authenticity of the foodstuffs, the international supplier fair for the food and beverage industry provides information on the latest technologies and services. The agenda focuses on trends and the residue analytics process as well as on current approaches for the prevention of food fraud. Experts estimate that around ten percent of the food and raw materials traded worldwide are affected by food fraud. The most frequently counterfeited foodstuffs are olive oil, honey, milk, fish as well as adulterated spice and nut mixtures.

The spotlight is on interdisciplinary methods

The spotlight is on interdisciplinary methods

Whether for allergen analysis, GMO detection, the determination of the animal species or detection of microbiological contaminations: The demands in the food safety section are just as diversified as the product spectrum of the exhibitors at the Cologne fair grounds. These range from measurement technology and accessories, sample preparation and analysis, to consumable supplies, through to whole laboratory facilities. In addition to immunological methods such as ELISA, the real-time polymerase chain reaction (PCR) is the basis for many food analysis examinations, because it enables high specificity and fast results. Whereas in the past the implementation of the thermal cycler necessary for the process was associated with high costs and intensive training, in the meantime affordable and compact devices are available that offer versatile applications in the everyday routine of smaller laboratories. This type of selective routine analyses will also be justified in the future.

Taking a look at Anuga FoodTec 2022 also underlines the fact that the days of isolated solutions are over. The development towards higher-resolution analysis devices is continually striding forward, because the quality and safety of a foodstuff is no longer determined merely by a few parameters but indeed by a variety of substances. The classic analytics that concentrates on the determination of the absolute concentration of known metabolic compounds reaches its limits here. The necessary marker substances initially have to be identified to determine authenticity parameters or detect a hitherto unknown change in a foodstuff. Metabolomics analyses are at the fore of this interdisciplinary approach. They are based on two methods: The nuclear magnetic resonance spectroscopy and the mass spectrometry, which are implemented coupled with chromatographic methods (gas chromatography and high performance liquid chromatography). These enable non-target analyses such as authenticity appraisal and the determination of the origin of foodstuffs.

The Laboratory 4.0 is taking shape

The Laboratory 4.0 is taking shape

Manual work is still the biggest timeconsuming factor in the laboratory. Food samples have to be processed fast and in accordance with the defined standards – demands that can be simplified with the aid of digitalisation and automation. Totally in line with the Laboratory 4.0, smart and networked analysis devices are under focus at Anuga FoodTec, which can be flexibly integrated into the IT environment across the entire value chain. The aim is to convert manual processes into automated processes and integrate them into the existing laboratory information management systems (LIMS). Based on these premises, scientists are presently working on rapid tests, which detect for instance within eight hours whether a foodstuff has been contaminated with salmonellae. Such molecular biological detection methods are already implemented in laboratories today, however these are rarely carried out as fully-automated processes or in the field of food diagnostics. To make this possible, the researchers are working on solutions that convert all hitherto manual processes into automated processes such as cultivation, enrichment, molecular biological duplication, through to detection.

Rapid hygiene control tests

Beyond the trend of characterising food more and more extensively by its ingredients and composition, above all practical cleaning and hygiene control tests are essential in the production environment. Ready-to-use culture medium plates are considered to be the ideal tool for monitoring hygiene. The method of detection is based on specific chromogenic substrates that are broken down into dyed products in the metabolic process of the cultivated microorganisms. After the incubation period, one can easily detect whether possible spoilage agents were found on the tested surface. However, it takes several days until the result is available. Rapid tests on the other hand don’t allow extensive screening when monitoring corporate hygiene, they do however provide a fast yes or no answer. Test sticks that react to nicotinamide adenine dinucleotide (NAD) and its phosphates are used for the purpose. The compounds are found in all living cells, including microorganisms as well as in food residues. A positive result is signalised by a change in the colour of the stick – and thus an impure surface. Such real-time tests are becoming increasingly more important for the food producers, because they detect deficiencies in the cleaning or disinfectant area or in the technological process within a few minutes.