Interstate Advanced Materials presents long-lasting material solutions for the food processing and production industry alongside the annual International Processing & Production Expo (IPPE), which runs from January 28th to January 30th in Atlanta, Georgia. Recognized as the world’s largest poultry, egg, meat, and animal food event, IPPE gives attendees access to the latest products and technology, education, and networking opportunities essential for supporting and advancing the industry’s future.

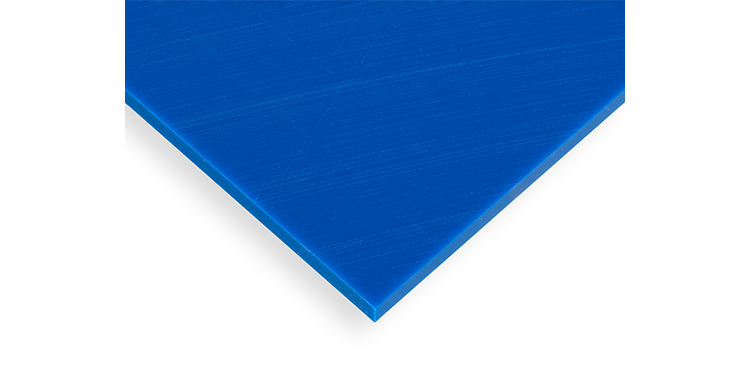

Tivar® HPV is a blue FDA-compliant, ultra-low-friction UHMW sheet engineered to improve motion and minimize wear in poultry, meat, and animal food equipment, including machines for conveying, cutting, packaging, mixing, and more. Its self-lubricating properties improve sliding performance, offering a near-zero level of stick-slip while eliminating squeaking and chatter. Tivar® HPV ensures maximum bearing life without deformation or excessive wear, protecting critical mating parts and reducing long-term maintenance costs. Tivar® HPV is ideal for wear strips, chain guides, chutes, liners, and other food processing components.

Natural HDPE cutting board is a trusted material for meat and poultry processing, offering long-lasting durability, minimal maintenance, and enhanced safety in food production environments. Its exceptional chemical and moisture resistance allows it to withstand harsh cleaning solutions and processing conditions without warping or degrading. HDPE’s non-porous surface prevents the absorption of bacteria, odors, and mildew, reducing the risk of contamination and supporting hygiene standards. HDPE is FDA and USDA-compliant, further reinforcing its suitability for applications ranging from commercial kitchens to large-scale food preparation facilities.

Copolymer polypropylene is a lightweight, highly formable, and robust material that excels in cold food processing applications. Its resistance to repeated impacts, abrasion, and chemicals makes it well-suited for equipment and surfaces exposed to continuous physical stress. Copolymer polypropylene provides greater flexibility and fatigue resistance than its homopolymer variant, ensuring dependable performance in components such as conveyor belts, wear strips, guides, and liners. Its low thermal conductivity helps maintain consistent temperatures in cold storage and food preparation environments, which is critical for meat, poultry, and fish processing. Copolymer polypropylene is FDA and USDA-compliant, making it ideal for direct food contact applications like bins, trays, containers, and packaging.

Interstate Advanced Materials looks forward to partnering with food processing and production experts as IPPE 2025 begins to find solutions for current industry challenges. Food processing and production specialists aiming to lower their material costs can save 30%+ on Tivar® HPV, natural HDPE, copolymer polypropylene, and other materials with an Interstate Advanced Materials membership.

Interstate Advanced Materials is a full-line distributor of high-performance sheet, rod, tube, plate, and bar, and proudly serves many diverse industries, including OEM, semiconductor, food processing, POP display, government, agriculture, automotive, and many others. With 10 locations nationwide and an online sales and support team, Interstate Advanced Materials provides full sheets and pallets, cut-to-size service, complex CNC, welding solutions, and full machining capabilities.

Interstate Advanced Materials is known for selling high-quality products, providing excellent customer service, and providing superior technical support. Excellence in all facets of the customer experience has been the cornerstone of Interstate Advanced Materials for over 40 years.