Cryogenic Processors, a trailblazer in the cryogenic freezing industry, is preparing to open a new, cutting-edge 115,000-square-foot cryogenic freezing and freeze drying facility in Paducah, Kentucky, in the fourth quarter of this year. The plant’s capabilities will include a large freeze drying operation that will supplement its cryogenic flash freezing, ultra-cold storage and finished product packaging under one roof, allowing Cryogenic Processors to serve a wide array of industries including food manufacturing, functional bacteria and cosmetics.

Cryogenic Processors has become known for its cryogenic freezing capabilities and is now adding the freeze-drying operation to its portfolio to help overcome a severe shortage of freeze-drying capability in the United States. Manufacturers typically must ship their product long distances to undergo the freeze drying process. Cryogenic Processors will be creating a one-stop shop approach to the overall process, saving manufacturers significant funds by handing their needs in its strategically situated mid-country facility.

“This state-of-the-art plant will not only enhance our production capabilities but also allow us to offer more comprehensive services to our clients,” said Kevin McClain, vice president and general manager of Cryogenic Processors. “This one-stop shop for cryogenic freezing, drying, packaging, storing and shipping will be an innovative and efficient solution for the needs of numerous different industries.”

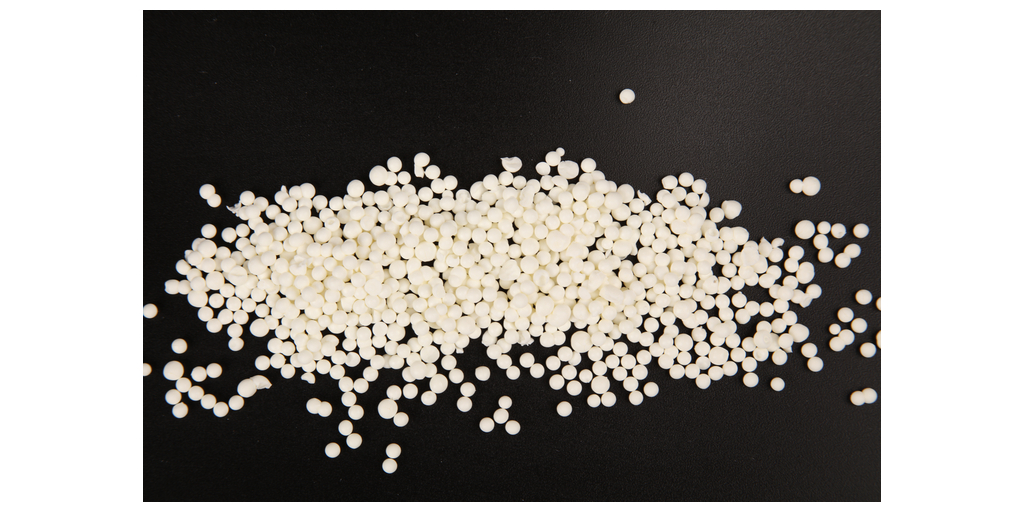

Cryogenic Processors utilizes contact cryogenic freezing capabilities as well as cryogenic pelletizer technology, employing liquid nitrogen and innovative machinery to process materials into beaded or granular form. This same technique is utilized by the iconic snack brand Dippin’ Dots to process its ice cream into small beads that are kept at subzero temperatures.

Cryogenic Processors utilizes contact cryogenic freezing capabilities as well as cryogenic pelletizer technology, employing liquid nitrogen and innovative machinery to process materials into beaded or granular form. This same technique is utilized by the iconic snack brand Dippin’ Dots to process its ice cream into small beads that are kept at subzero temperatures.

With 30 years of innovation and improvements, pelletizing technology has been improved and adapted to meet the unique needs and requirements of food and nutraceutical companies around the world. The pelletizing freezing method offers efficiency, consistency and high capacity with low processing loss in a compact package. Cryogenic Processors currently utilizes pelletizer technology at its first facility in Nashville, Tennessee, and will scale its operation and offerings with the new Paducah plant.

The new Paducah facility was designed to set a new standard in the cryogenic freezing industry and expand freezing capabilities to a broader range of products. It will feature three isolated pelletizing rooms, each equipped with advanced blending systems and a standard conical pelletizer with an increased capacity of 1000 kg/h. Once pelletized, storage will be available at temperatures as low as -60°C (-76°F).

The upcoming facility is not just an expansion of production capacity; it represents Cryogenic Processors’ commitment to innovation, quality and customer service. By providing a one-stop solution for cryogenic freezing, freeze drying and packaging, Cryogenic Processors is well-positioned to serve the needs of companies exploring flash freezing food, functional bacteria, flavorings, protein isolates, cosmetics and more.