CAPTEK Softgel International, a leading contract manufacturer of dietary supplements has officially begun gummy supplement production in La Mirada, California. The new 60,000 square foot manufacturing facility offers turnkey gummy formulations, custom flavorings and bottling solutions. Moreover, it marks a carefully planned expansion for the company to meet increasing consumer demand.

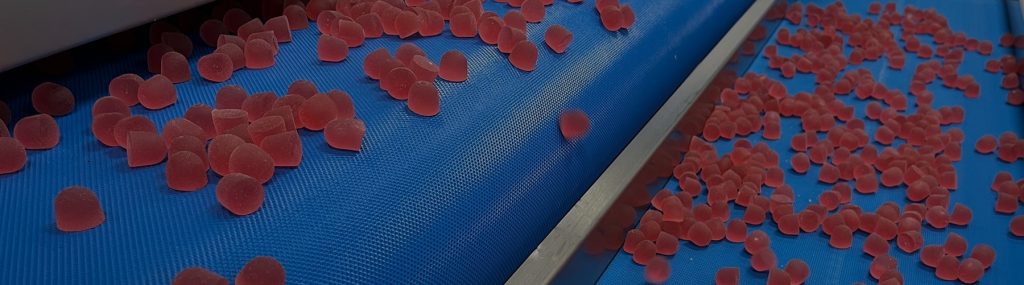

This new manufacturing facility is equipped with the latest technology and equipment necessary to produce 1.5 billion gummies annually in a wide range of shapes such as gummy bears, gumdrops, and cubes. Its starch-free production lines can produce a variety of gummies, including pectin, agar, carrageenan, gelatin, and combination-based gummies which allows for flexibility in innovation and makes them inherently gluten-free. With pilot-scale equipment, CAPTEK can seamlessly scale up which allows the company to produce samples for evaluation using equipment that closely mirrors production, increasing time to market.

The SQF certified facility employs nearly 100 Associates who have 25+ years of combined experience in developing and manufacturing a variety of nutraceutical gummies and combining multiple nutrients to produce some of the best tasting gummies on the market. The team is also working to obtain Organic, Kosher, and Halal certifications, among others.

“We are thrilled to introduce our advanced gummy manufacturing capabilities,” said Randy Bridges, Chief Executive Officer at CAPTEK Softgel International. “This new facility is expected to substantially increase our capacity and position our organization to manufacture a wider array of products to satisfy changing customer demand. This investment will further position CAPTEK as a leader in contract manufacturing as well as play a significant role in our future growth plans.”