Spread Co., Ltd. has developed the Techno Fresh processing method which allows for an increase in the shelf life of cut lettuce of up to 2 times, while preserving freshness, taste, and quality. Spread has also started construction on the first large-scale salad processing plant to utilize the method – Techno Fresh Hadano near Tokyo.

Development of Techno Fresh

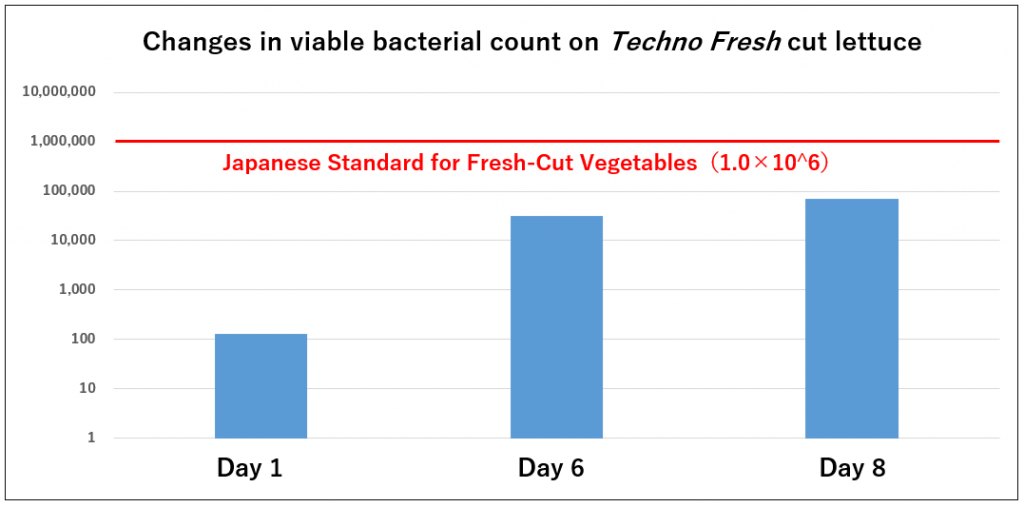

Food insecurity is a global problem, with 1.3 billion tons of food loss occurring every year, while approximately 800 million people are suffering from famine. Food waste is an important problem in Japan specifically, since it ranks as the 14th country with the highest amount of food waste, with over 8 million tons of food thrown away in 2021 *1. One reason for Japan having a high food waste rate is its strict regulation concerning the expiration dates for products. For example, one of the standards commonly used for fresh-cut vegetables requires viable bacteria count to be lower than 1,000,000 for 1g of the product. Due to this, the shelf life for fresh-cut lettuce in Japan is commonly set at 3-4 days.

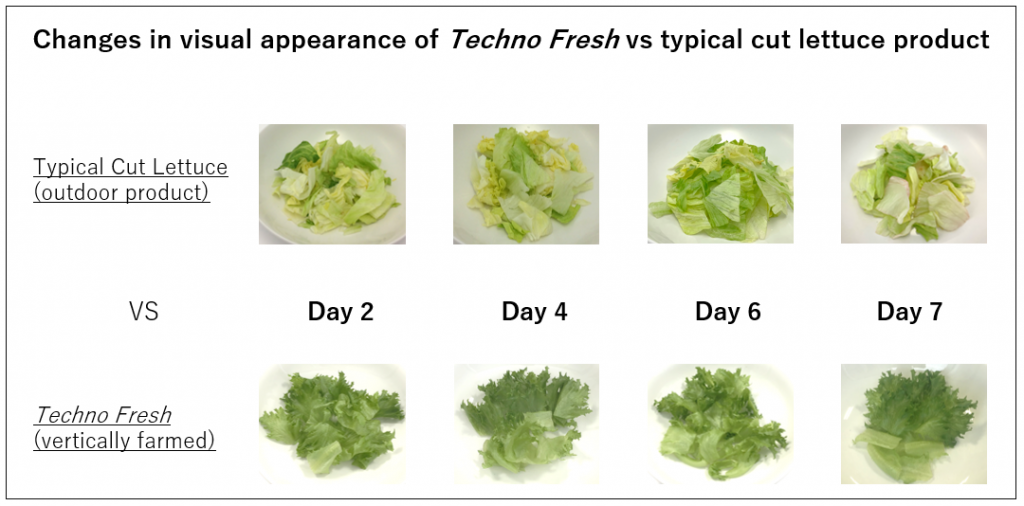

The Techno Fresh processing method uses pesticide-free, pristine lettuce, that is grown in a highly hygienic environment within Techno Farm and combines it with the in-house developed processing technologies that prevent bacteria from increasing. Through this method Spread was able to enhance the shelf life of the cut lettuce by up to 2 times and has become the first company to achieve record-breaking 6 days shelf life for a fresh-cut lettuce product in Japan. Additionally, the Techno Fresh method prevents lettuce from browning/discoloration and doesn’t have the unpleasant smell that is associated with certain washing agents.

Comparative Data for Techno Fresh (changes over time) *2

Sample size: n=13

Sample size: n=13

Techno Fresh Hadano

Techno Fresh Hadano

Techno Fresh Hadano is the first processing facility by Spread, and is the first facility to implement theTechno Fresh system. This next-generation processing factory will process 8 tons of lettuce per day while automating 85% of the processes, including implementation of the world’s first AI-based lettuce core remover. Automation will allow for a drastic improvement in productivity, while the dedicated processing design developed in-house makes it extremely resorce-efficient, lowering water usage by 55% *3 .