The ingredients used in shakes range from milk or whey powders to collagens, vitamins and bioactive plant substances. These raw materials are usually fine powders with poor processability, which can quickly turn an on[1]the-go shake into a frustrating experience. Solubility is key during formulation and all the ingredients should dissolve, disperse or swell simultaneously — with no lumps or residue. It’s what consumers expect and take for granted; but, market success can pivot on a number of essential characteristics: preparation in a matter of seconds, good flavour and the right mouthfeel (fig. 1).

The wettability factor How quickly an instant product dissolves when shaken or stirred depends on the wettability of its dry particles. For hydrophobic substances, an emulsifier in the formulation can help. To dissolve properly, however, a powder particle must first be completely immersed in the liquid. Spray-dried powders, for instance, are very light and often remain on the surface; they become enclosed by the liquid to form lumps when wetted and then only dissolve slowly.

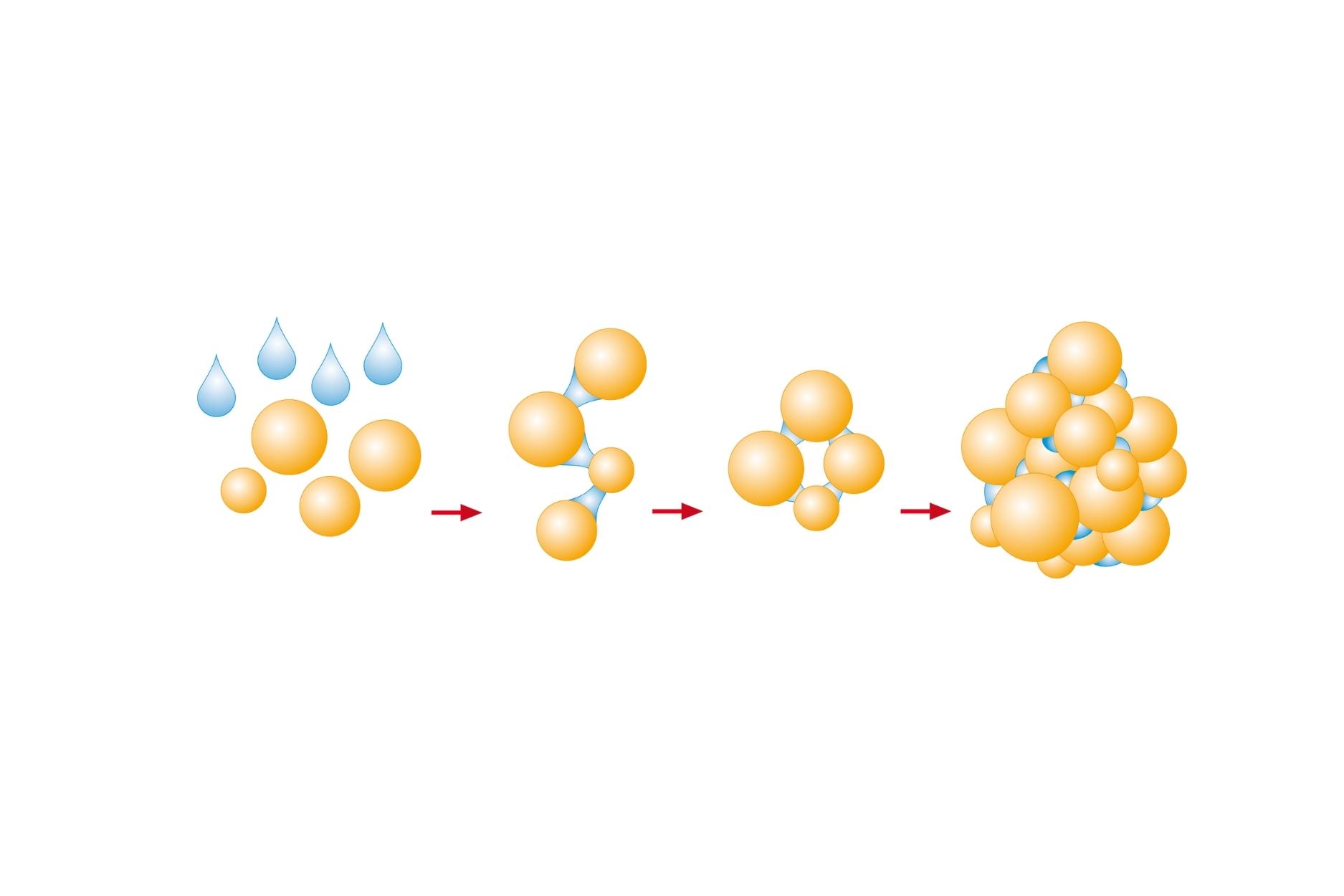

Particles with a porous structure (fig. 2), by contrast, are heavier and sink quickly. Liquid penetrates their capillary-like tubes and promotes rapid disintegration to form individual particles, which then dissolve more quickly. Powder agglomeration enhances this process and is best done with a fluidised bed system. As a procedure of choice, it gently and reproducibly produces dust-free and free-flowing agglomerates from fine powders, which are perfect for instant shake products.

Fluidised bed: grain-to-grain particle formation

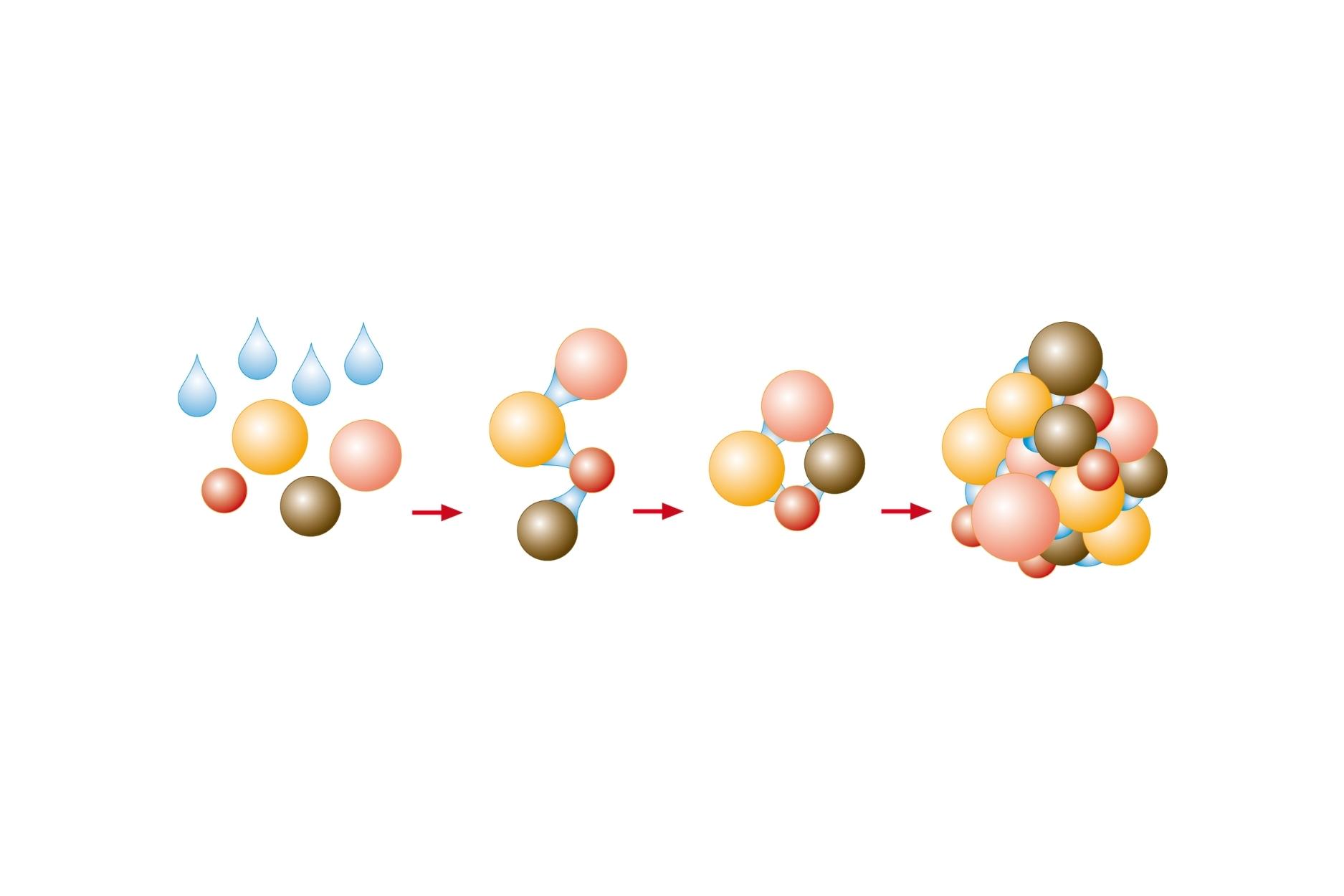

The principle of agglomeration, also known as build-up agglomeration, is based on the formation of solid bridges that bind fine powder particles together and allow them to grow — grain-to-grain — into larger, loosely structured masses. To do this, liquids or a vapour is employed to moisten the particle surface and, initially, encourage liquid bridges to form between the particles. During the subsequent drying phase, solid bridges then develop from the previously dissolved product or from a polymer added to the spray liquid. (fig. 3 & 4)

When agglomerating powders into granulates, fluidised bed technology allows several processes to be combined into one unit operation. Such a system consists of the air supply chamber, the process chamber, the spraying device and the filter system. The process air controls the heat and material transport parameters by keeping the feed and the starting product — usually the fine powder — in suspension by means of an upward flow of hot air.

During mixing, the particles collide with each other and, as such, the volume flow and gas velocity are adjusted to minimise abrasion. Fine particles that remain stuck in the filters are removed by induced pressure surges and fed back into the process. This allows them to be reagglomerated. As soon as a level of uniform fluidisation has occurred, and the point at which the fixed bed becomes a fluidised one has been exceeded, a liquid or suspension is sprayed into the chamber. This solvent evaporates in the hot air flow. Loose agglomerates form because three distinct forces are at work: permanent contact, collision and the accumulation of liquid droplets. The process then continues until the desired particle size is reached.

Capillary cohesion forces and surface boundary tension cause the particles to stick together. The resulting (coarser) granulate mix has different properties to the original powder: it is significantly more free-flowing and its electrostatic charge is reduced. Owing to the porous structure and the capillary like tubes on the surface, the particles are easier to wet and dissolve more quickly.

Factors influencing agglomerate formation

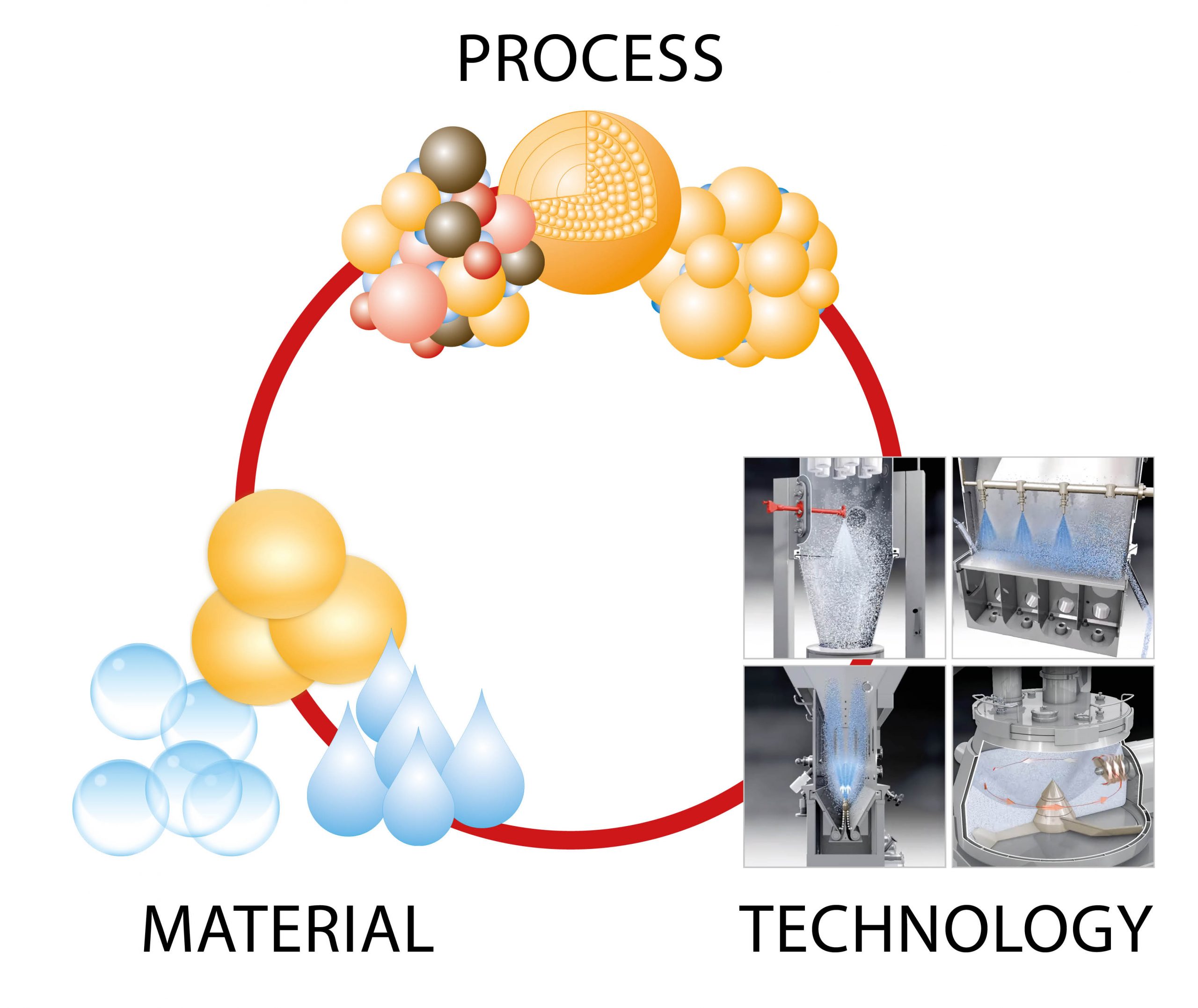

The success of the agglomeration process is determined by the chemical and physical properties of the formulation, the process and the system’s geometry. (fig. 5) Homogenous moisture distribution in the product bed is the starting point for the individual particles to combine into an agglomerate. For this purpose, a nozzle is placed above the product container in the so-called top spray process. This means that all the particles in the product container must pass through the spray mist. As a result, the finest particles readily bind to coarser ones and are not discharged into the filter. The height and position of the spray nozzle can be adjusted to optimise the process.

Moisture is the key parameter for successful agglomeration. Operational properties such as particle size, the binder liquid and the stickiness of the product all contribute to the density and stability of the product. The particle size of the starting material is also important: to incorporate coarser particles into an agglomerate, greater adhesive forces are required than for smaller ones. The adhesive forces are formed by interparticle solid bridges. These, in turn, arise from the liquid bridges derived from large binder droplets. Fine particle fractions can easily become too moist as a result. (fig. 6)

Extreme differences in size should therefore be equalised, such as by grinding coarse particles. Conversely, fine powders agglomerate with fine spray droplets. It should be noted here that the top spray process involves spraying against the air flow and that the spray liquid can be dried directly if the atomisation pressures are too high. In this case, the agglomeration process is best supported by additional humidification of the supply air.

Process development and scale-up

To achieve an optimum product with the desired properties, it is essential to harmonise the formulation, the process and the system. For this purpose, as many parameter settings as possible — such as temperature, air volume, spray rate and atomisation pressure — should be investigated at laboratory scale to clearly determine the most influential factors.

Once a stable, reproducible process has been determined, it can be safely scaled-up to production capacities in just a few steps. The agglomeration of powders can be done in both batch and continuous modes. The most significant factor here is the intended annual production volume.

At its technology centre, Glatt provides access to sophisticated technologies and support in formulation, product- and process development, which can all be adapted to individual customer requirements. This always starts with tests on a laboratory-scale system. The in-house analytical team performs in-process analyses to quickly adjust particle properties such as size and bulk density. Then, to facilitate scale-up, process and operating parameters are determined in pilot studies.

Working closely with the customer, product quantities from the kg scale up to several 100 kg are produced, analysed and optimised in the technology centre. From feasibility studies to market-ready product, we examine the entire process chain. The resulting powders, pellets or granulates can be produced, filled, packaged and delivered directly in agreed quantities via Glatt’s contract manufacturing services. And, in addition to the development of customer-specific and functionalised products and processes, Glatt Ingenieurtechnik offers a wide range of services from project initiation, development and implementation through to the production/supply of turnkey plant.