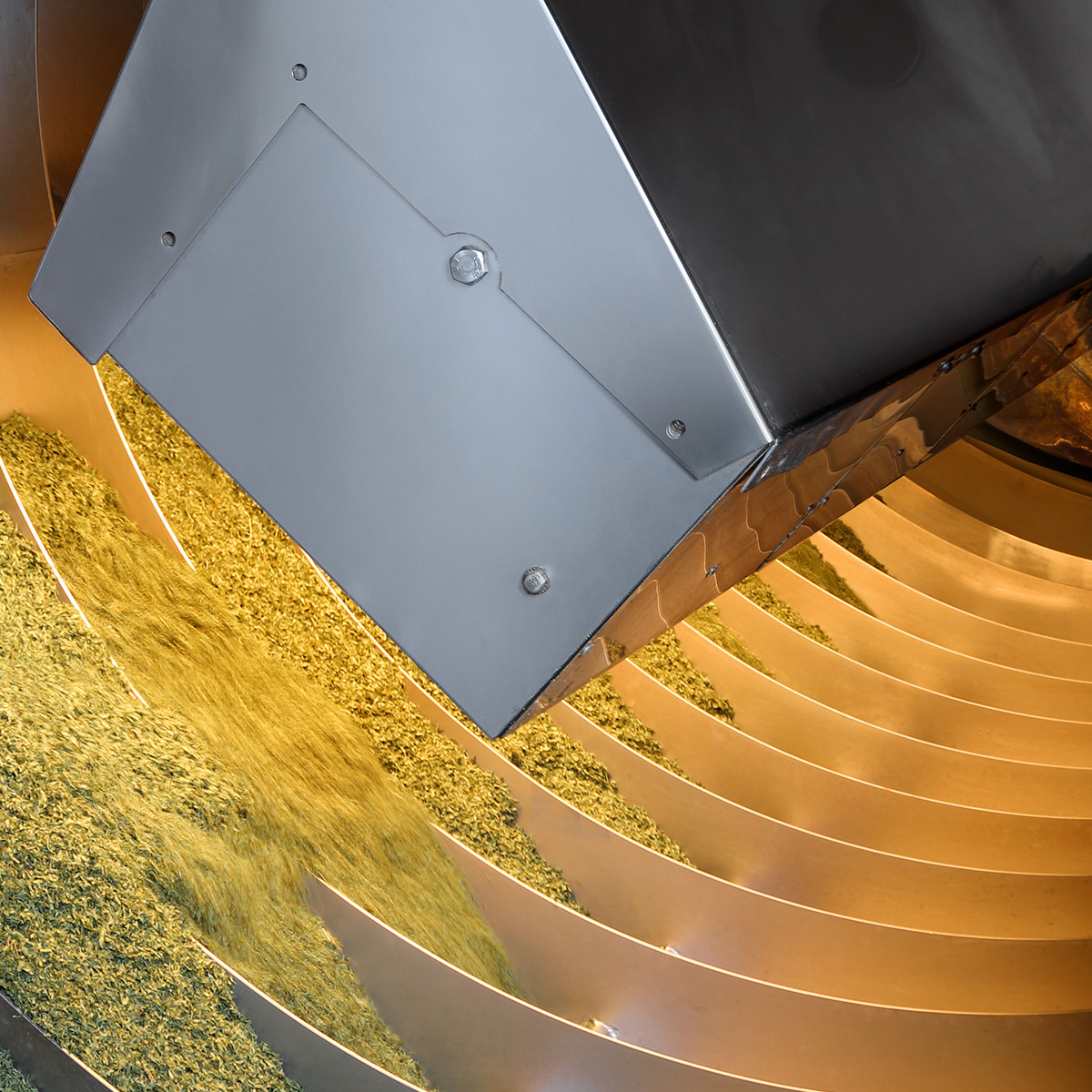

High-quality and sensitive raw materials, such as dried spices, herbs, seeds, nuts, and many other bulk food products, can be effectively safeguarded against microbial contamination (such as salmonella, E. coli, molds, or yeasts) through the use of KREYENBORG’s FoodSafety Infrared Rotary Drum (FS-IRD). This innovative technology not only eliminates contaminants but also preserves the integrity of essential ingredients, vitamins, and aromas, and the product’s appearance, as well.

Unlike with the application of ethylenoxid (EtO), propylenoxid (PPO), or irradiation methods for sterilization of products such as herbs and spices, infrared light is an entirely natural process, suitable for both organic and conventional food products. The FoodSafety-IRD is user-friendly and easy to clean, making it a versatile solution not only for sterilization but also for roasting, drying, coating, and stock protection.

When products are treated with infrared light in the FS-IRD, they are rapidly heated from the inside out in just a few minutes, resulting in gentle sterilization, roasting, or drying. Throughout the process, the FS-IRD adjusts the intensity of the infrared lamps and the product and process temperatures automatically to maintain an optimal treatment temperature. Continuous and gentle mixing ensures a uniformly high-quality end product. Temperature and dwell time can be easily and quickly adjusted, offering flexibility during processing. Additionally, the direct-action principle of infrared light significantly reduces energy consumption.

When products are treated with infrared light in the FS-IRD, they are rapidly heated from the inside out in just a few minutes, resulting in gentle sterilization, roasting, or drying. Throughout the process, the FS-IRD adjusts the intensity of the infrared lamps and the product and process temperatures automatically to maintain an optimal treatment temperature. Continuous and gentle mixing ensures a uniformly high-quality end product. Temperature and dwell time can be easily and quickly adjusted, offering flexibility during processing. Additionally, the direct-action principle of infrared light significantly reduces energy consumption.

To make the sterilization of products even more effective, a fine water mist is typically sprayed during the sterilization process. This is done after the product has reached the desired process temperature through infrared light, making it possible to regulate moisture content inside the product. Surface evaporation further enhances germ reduction, and the product is additionally preserved through the cooling process.

The FoodSafety-IRD is a cutting-edge solution for improving the sterilization process of products while also placing strong emphasis on resource conservation. Powered only by electricity, it functions as fully CO2-neutral, aligning with the ever-growing global focus on environmentally responsible practices. In a world where many companies are already harnessing alternative energy generators like solar panels or acquiring green electricity from their providers, the FoodSafety-IRD stands as a prime example of sustainable technology.

KREYENBORG offers further plant components such as for cooling, conveying, mixing and storage, as well as comprehensive solutions, including control systems.

Visit KREYENBORG at Food Ingredients Europe in Frankfurt for more information – booth B144 in hall 3.1.!