METTLER TOLEDO Product Inspection is proud to announce the latest version of its advanced data management software, ProdX™. Designed for food manufacturers, ProdX™ 2.6 is set to improve data handling, quality control and operational efficiency in the food industry.

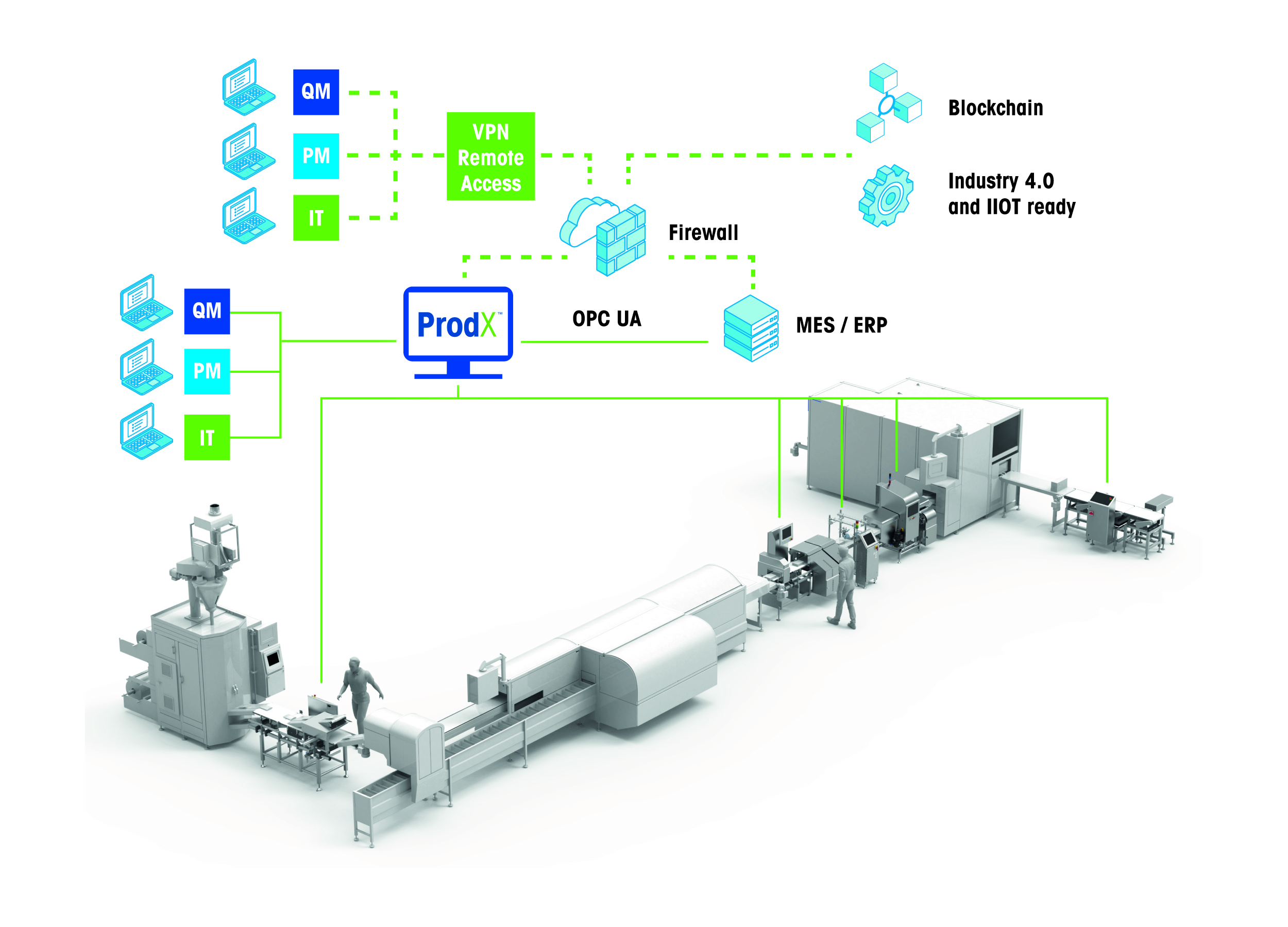

The primary objective behind the new software enhancements to ProdX™ 2.6 was the commitment of METTLER TOLEDO to meeting the exacting demands of food manufacturers searching for comprehensive, efficient and data-driven solutions. Positioned as a cornerstone of quality control and data management in food production, ProdX™ 2.6 seamlessly integrates with METTLER TOLEDO product inspection equipment – x-ray inspection, metal detection, checkweighing and vision inspection – facilitating the secure collection and management of critical inspection data.

Whether monitoring reject statistics, contamination events or generating reports, the update empowers users with a high level of accessibility and automation. In industries such as food manufacturing, where precision and efficiency are paramount, ProdX™ 2.6 addresses these priorities head-on. It allows manufacturers immediate access to data to make informed decisions to improve production line performance and meet the highest quality standards.

Improving Data Management for Food Manufacturers

Improving Data Management for Food Manufacturers

ProdX™ plays a pivotal role in food manufacturing by seamlessly collecting and safeguarding inspection data from Product Inspection devices. It acts as a secure repository, archiving this critical data in a tamper-proof central server while offering the flexibility to generate ad-hoc or automated reports.

With the newly updated ProdX™ 2.6, METTLER TOLEDO meets customer requirements better by offering several key additional benefits, including:

Optimised Web Dashboard – Data at Your Fingertips: In the latest update, ProdX™ 2.6 now features an optimised web dashboard. This advanced web-based interface offers users the ability to access and monitor their data on smart devices like tablets and smartphones, eliminating the need to install additional software applications.

Users can effortlessly review critical information, such as reject statistics and contamination events, and generate reports by simply accessing the dashboard via a web browser. This update opens new avenues for data accessibility, making it available to anyone connected to the network, whether wirelessly or through a cable connection. Users with VPN access can also conveniently view data through their web browser.

Streamlined User Experience – Logging into Inspection Equipment: The updated software also simplifies the user experience by enabling workers to use their ProdX™ login credentials to access METTLER TOLEDO product inspection equipment. This integration enhances operational efficiency and offers a seamless transition between tasks, promoting ease of use.

Automated Reporting – Valuable Insights Readily Available: Another significant improvement to ProdX 2.6 is its capability to automate the generation of final evaluations and summary reports. This advancement streamlines reporting processes, allowing users to trigger final evaluations at the end of product runs, shifts or days automatically. Additionally, users can program automated reports in various formats and delivery methods for daily, weekly and monthly summaries. By automating these processes, users gain valuable insights by easily comparing runs, shifts and specific time frames, identifying opportunities for improvement.

Automated Reporting – Valuable Insights Readily Available: Another significant improvement to ProdX 2.6 is its capability to automate the generation of final evaluations and summary reports. This advancement streamlines reporting processes, allowing users to trigger final evaluations at the end of product runs, shifts or days automatically. Additionally, users can program automated reports in various formats and delivery methods for daily, weekly and monthly summaries. By automating these processes, users gain valuable insights by easily comparing runs, shifts and specific time frames, identifying opportunities for improvement.

Enhanced Changeover – Flexibility and Improved Sustainability: The new software also provides food manufacturers with increased flexibility and efficiency during product changeovers. Manufacturers can now switch over their product inspection systems simultaneously or selectively, either from a master device or remotely. This feature is particularly valuable in industries with extended manufacturing processes, such as chocolate production, where batch changeovers can occur while products move along the production line.

This newly enhanced product changeover functionality not only reduces downtime but also minimises product wastage, promoting sustainability and cost savings. Additionally, as it is a paperless system, ProdX™ helps manufacturers to contribute to environmental sustainability by reducing daily paper usage.

Peter Spring, ProdX™ Product Manager at METTLER TOLEDO, says, “ProdX™ 2.6 represents a leap forward in manufacturing productivity. By simplifying and automating documentation and reporting processes, this new version eliminates the arduous task of manual data compilation that manufacturers once grappled with. Administrative productivity receives a substantial boost, freeing up valuable time and resources that can now be channeled into more strategic and value-added activities. These combined enhancements, alongside the sustainability improvements ProdX™ 2.6 offers, are poised to greatly improve the way food manufacturers operate, enhancing productivity, efficiency and sustainability”.

Peter Spring, ProdX™ Product Manager at METTLER TOLEDO, says, “ProdX™ 2.6 represents a leap forward in manufacturing productivity. By simplifying and automating documentation and reporting processes, this new version eliminates the arduous task of manual data compilation that manufacturers once grappled with. Administrative productivity receives a substantial boost, freeing up valuable time and resources that can now be channeled into more strategic and value-added activities. These combined enhancements, alongside the sustainability improvements ProdX™ 2.6 offers, are poised to greatly improve the way food manufacturers operate, enhancing productivity, efficiency and sustainability”.

Other key updates to the software include:

Product Validation Capability – Security and Compliance: For x-ray inspection systems, ProdX™ 2.6 introduces a product validation capability, a crucial feature for maintaining product setting integrity. This capability provides a visual indicator to confirm that the system is inspecting a product using validated setting parameters. In case any parameters are altered, the login used and the changes made are recorded. Additionally, the x-ray system’s product parameters are now stored in ProdX™ for remote viewing, regardless of whether these parameters can be edited remotely.

Open Platform Communication Unified Architecture (OPC UA) Weighing Technology Integration – Seamless Connectivity: ProdX™ now also complies with the Open Platform Communication foundation’s weighing technology companion specification, facilitating effortless integration with checkweighers within this standard. This integration not only streamlines the connection between ProdX™ and third-party checkweighers, but also allows for seamless data exchange, enhancing overall operational efficiency and providing manufacturers with real-time insights critical for precision control and compliance.