Mettler-Toledo Product Inspection has redesigned its C2 High-load Checkweighing portfolio, capable of weighing heavy loads of up to 35kg. The portfolio is positioned to help manufacturers combat rising costs, plus increase reliability and serviceability. This mechanical re-engineering applies to the Mettler-Toledo C21 StandardLine and C23 PlusLine checkweighing systems for precision weighing and completeness checks of packaged food, pharma, cosmetics and pet food products.

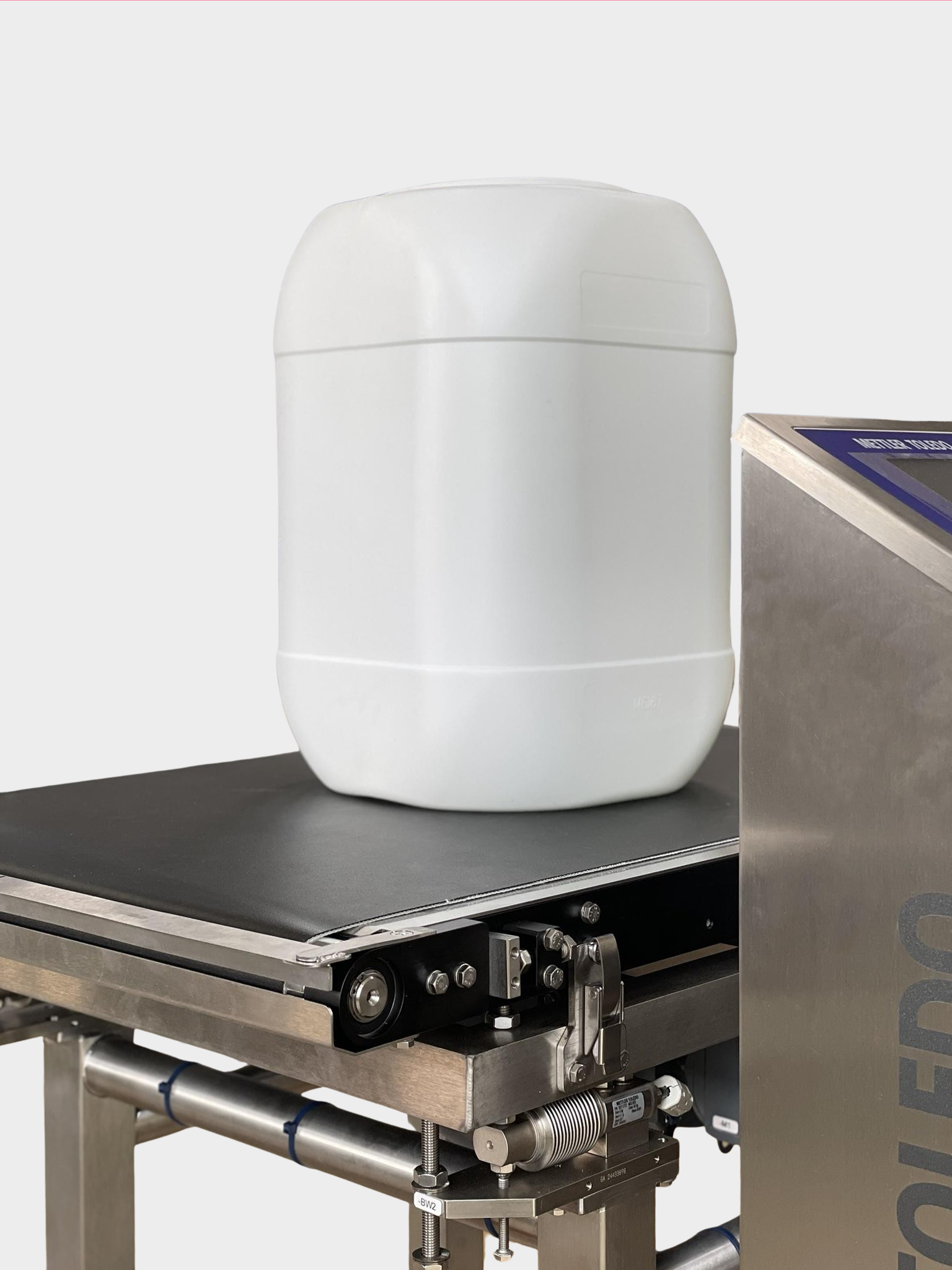

The primary objective behind the redesign is to boost productivity for manufacturers, and to better address the specific requirements of those seeking robust, reliable and cost-effective checkweighing solutions for heavy loads. C2 High-load checkweighers are typically installed at the end of the production line, where they perform quality assurance operations such as case completeness checks by verifying the presence of the correct number of bottles in a case. This addresses machine reliability and cost-effectiveness, which are key concerns for manufacturers.

The primary objective behind the redesign is to boost productivity for manufacturers, and to better address the specific requirements of those seeking robust, reliable and cost-effective checkweighing solutions for heavy loads. C2 High-load checkweighers are typically installed at the end of the production line, where they perform quality assurance operations such as case completeness checks by verifying the presence of the correct number of bottles in a case. This addresses machine reliability and cost-effectiveness, which are key concerns for manufacturers.

Smarter Cost Management & Total Cost of Ownership: The newly re-designed C2 High-load Checkweighing portfolio, now better meets customer requirements, while also offering several additional benefits that lead to reduced run costs and enhanced performance. With a 50% reduction in motor power consumption, the new design brings significant energy savings, reducing operational expenses. Additionally, the portfolio helps minimise stock costs by reducing different wear parts by 50%, simplifying maintenance and improving inventory management thereby lowering Total Cost of Ownership (TCO). Integration with ProdXTM and Open Platform Communications (OPC) facilitates increased automation, reducing manual work and optimising overall costs.

Data & Digitalisation: ProdX™, data and quality management software from Mettler-Toledo, integrates data from multiple applications, devices and processes, enabling more informed decision-making. With a wealth of data related to quality control, contamination detection and package integrity, ProdX™ empowers manufacturers to optimise energy consumption, identify environmental influences and create predictive maintenance schedules, which enhances overall efficiency in the food industry. Its seamless integration with existing systems and applications opens up exciting possibilities for comprehensive data analysis and informed decision-making.

Increased Serviceability: The C2 Checkweighing portfolio’s enhanced serviceability and design provide maximum efficiency and reliability. The system’s easy and fast belt and roller replacement capabilities minimise downtime and maintenance efforts, helping to deliver uninterrupted operations. The reduced number of different wear parts also simplifies maintenance procedures and lowers operational costs. With an average three times higher bearing lifetime in the conveyor rollers, the system’s reliability is significantly improved, helping to further enhance its overall performance.

Optimized Performance: The redesigned C2 Checkweighing portfolio excels in robustness and ease of cleaning, for optimal performance. Featuring an optimised frame design with fewer horizontal surfaces, the system enables easier cleaning and minimises dust accumulation, maintaining cleanliness and helping to comply with hygiene standards. This streamlined design enhances the efficiency and accuracy of the checkweighing process.

Consistently Precise Results: Reliability and accuracy are at the forefront of the C2 Checkweighing portfolio. The integration of the latest filter technology enhances the system’s ability to deliver accurate and reliable weighing results, for quality control and compliance with stringent standards.

Sustained Support: Service support is also available with all product inspection equipment from Mettler-Toledo. With a global network of skilled service technicians and technical experts, Mettler-Toledo customers have access to prompt and reliable support whenever and wherever it’s needed. Whether it’s installation, training, maintenance, calibration or troubleshooting, the dedicated service team supports customers to maximise their production uptime and equipment performance.

Future Proof Technology: The C2 Checkweighing portfolio also offers exceptional application flexibility. Designed to accommodate diverse product handling needs, the portfolio includes large conveyor sizes capable of supporting belt widths up to 600mm. This expanded capacity allows for the inspection of even larger products, providing flexibility and versatility. With a wide range of conveyor sizes available which are tailored to specific application requirements, the C2 Checkweighing portfolio can adapt to various product dimensions and configurations, facilitating seamless integration into production lines.

To meet different operational conditions, the C2 Checkweighing systems are available in both IP54 and IP65 designs, providing the necessary protection against environmental factors such as dust, moisture and other contaminants. This versatility enables the systems to thrive in a wide range of operating environments while maintaining optimal performance and accuracy.

“We are very excited to be announcing our redesigned C2 Checkweighing portfolio, which sets a higher degree of precision and efficiency in high load checkweighing. With enhanced accuracy and improved user-friendly features, the C2 series allows seamless integration into production lines while delivering reliable and consistent weight measurement,” said Dirk Bettels, Senior Project Manager at Mettler-Toledo. “We believe this enhancement shows our commitment to continuous innovation and providing our customers with the most advanced checkweighing solutions in the industry.”

The systems benefitting from this redesign are:

The C23 PlusLine Checkweigher – a compact and versatile solution for precise weight control of heavy loads. With its modular design and customisable features, it offers seamless integration in challenging environments. The checkweigher provides high accuracy, meeting Measuring Instruments Directive (MID) requirements and reducing product waste. Its intuitive operation, multi-language support, and clear machine messages enhance usability. Equipped with strain gauge technology and supported by a global service network, the C23 PlusLine delivers reliable and scalable performance. Connectivity options for IoT and Industry 4.0 initiatives enable real-time data access and analysis. Overall, the C23 PlusLine combines accuracy, flexibility and reliable performance for optimal checkweighing operations.

The C23 PlusLine Checkweigher – a compact and versatile solution for precise weight control of heavy loads. With its modular design and customisable features, it offers seamless integration in challenging environments. The checkweigher provides high accuracy, meeting Measuring Instruments Directive (MID) requirements and reducing product waste. Its intuitive operation, multi-language support, and clear machine messages enhance usability. Equipped with strain gauge technology and supported by a global service network, the C23 PlusLine delivers reliable and scalable performance. Connectivity options for IoT and Industry 4.0 initiatives enable real-time data access and analysis. Overall, the C23 PlusLine combines accuracy, flexibility and reliable performance for optimal checkweighing operations.

The C21 StandardLine Checkweigher – a robust solution designed for heavy loads, offering seamless integration into any production line. With its user-friendly operation and clear machine messages, it provides efficient and easy operation, requiring minimal training. The checkweigher has various connectivity options, allowing effective data communication for centralised system control. Its robust design, powered by the Mettler-Toledo strain gauge weighing technology, delivers accurate weighing results. The C21 StandardLine is a cost-effective choice for end-of-line completeness checks, providing reliability and accuracy for product weighing and simple MID-approved checkweighing applications.

The C21 StandardLine Checkweigher – a robust solution designed for heavy loads, offering seamless integration into any production line. With its user-friendly operation and clear machine messages, it provides efficient and easy operation, requiring minimal training. The checkweigher has various connectivity options, allowing effective data communication for centralised system control. Its robust design, powered by the Mettler-Toledo strain gauge weighing technology, delivers accurate weighing results. The C21 StandardLine is a cost-effective choice for end-of-line completeness checks, providing reliability and accuracy for product weighing and simple MID-approved checkweighing applications.