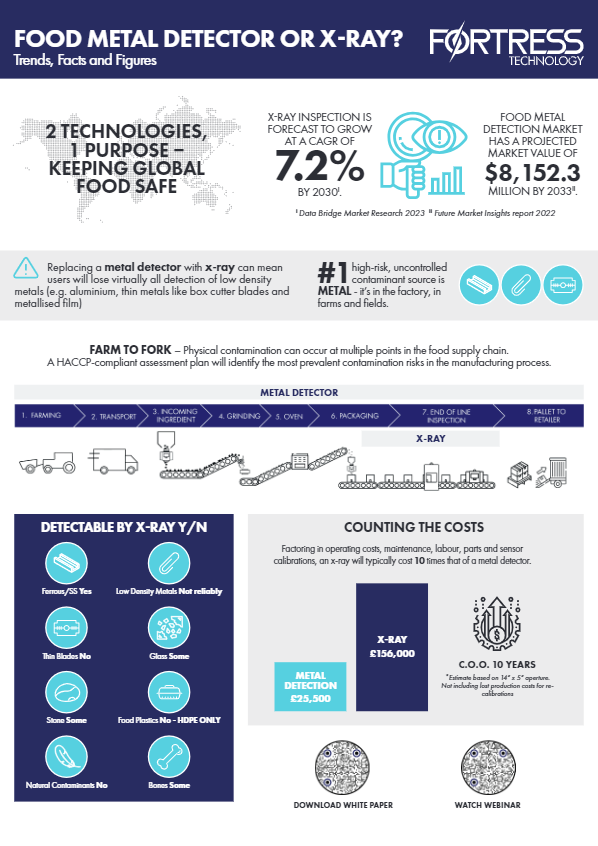

Demand for both technologies continues to grow (see infographic). Fortress attributes this to the wider adoption of all inspection technology. However, the company is adamant that one won’t necessarily supersede the other. Why? It’s down to the fact that each technology has its respective strengths and limitations.

As food processors strive to curtail rising food prices through widespread adoption of automation, contamination risks have risen incrementally. The threat posed by a recall and enhanced quality control is certainly driving food factories to implement a more robust ‘best in class’ contaminant detection strategy. For some this might be metal detection, others x-ray, but for a number it could be a combination of the two.

“The decision to invest in x-ray or metal detection equipment is dependent upon a manufacturer’s requirements. Both technologies come with their own advantages; neither should be a replacement for good manufacturing practices. Rather food contaminant detection units should always complement the process based on needs and risks,” highlights European Managing Director Phil Brown.

Rocks … Metals … Bones

Rocks … Metals … Bones

The most common high-risk contamination culprit remains metal. Often caused by fragments that break off during mechanical cutting, blending and processing operations, or from box cutter blades.

Each sector has its own set of more prevalent risks. With convenience meals, there can be more than eight production steps between sourcing ingredients to packing, and more than five different product types included in an individual meal. This increases the risk of metal and plastic contaminations. Intrinsic contaminants are common in protein ingredients, such as bones or teeth from fish, meat and poultry. They can also occur in fresh produce, for example fruit and vegetable stones and seeds or egg shells. The other is human PPE risks from hairnets and masks.

“An x-ray machine is a density detection system and will therefore identify denser contaminants like glass, ceramic and bone. However, there are certain metals an x-ray cannot detect in food products, including lightweight foil strips found in PPE and very thin box blades. Although visible to a metal detector, in contrast there’s not enough density differential between the lower density metal and the product being inspected for an x-ray to pick this up,” explains Phil.

Running costs

A key consideration in any food processor’s business is the performance and efficiency of production equipment. Aside from the upfront price, which varies significantly depending on specifications, aperture size etc. the most overlooked cost, reports Fortress, is often the maintenance, calibration and testing of x-ray equipment. With metal detectors this is minimal. That’s not always the case with x-ray. As a general rule, factoring in the operational and maintenance costs, x-ray systems can sometimes cost 10 times that of a metal detector (see infographic).

Notably, x-ray machines are not well suited to in-house mechanics or repairs. Safety concerns, the cost of training, and dealing with potentially high-voltage components means manufacturers usually have to bring in engineering expertise. There’s also the cost of performing legal safety inspections.

Additionally, spare part prices are typically much higher than a metal detector. Fortress research suggests over five years manufacturers can spend in the region of £20,000 (€24,000) on replacement x-ray components, compared to the relatively insignificant £1,000 (€1,200) on a metal detector.

The reason for this is metal detectors have less to go wrong. There are no heat sources and they can quickly be repaired by maintenance teams. Most food plants can easily get a detector up and running with spare parts held in stock, or with some adjustments to settings. It’s also feasible to troubleshoot any issues that arise with remote support.

Where on the line?

Where on the line?

Metal detectors are as effective for in-process inspections as they are for end-of-line checks. However, x-ray machines are typically located towards the end of the processing line, often after packaging.

Although x-ray machines are built to withstand water, they don’t like it around them. Similarly, dust, heat and cold temperatures can shorten an x-ray’s life span, including their components. For this reason, x-ray machines are rarely deployed upstream in bulk, farming, gravity, ingredient or raw processing areas in a food production factory.

Metal detectors lend themselves much better towards more challenging environments, including flour and rice mills, as well as snack gravity applications where product is moving through an aperture at very high speed.

Safety truths

Seeing an x-ray symbol on the side of the machine can be a perceived risk. Modern food x-ray machines are designed to shield operators from harmful exposure to x-rays. Fortress x-ray units, for example, feature protective high-density acrylic windows with interlocked doors. However, training, including regular refresher training, is critical, ensuring all operatives are following the correct safety precautions.

When the x-ray tube is energised, x-rays are produced and radiation is generated. When turned off, radiation dissipates. There are strict regulated radiation leakage and dosage limitations when using a food inspection x-ray.

When the x-ray tube is energised, x-rays are produced and radiation is generated. When turned off, radiation dissipates. There are strict regulated radiation leakage and dosage limitations when using a food inspection x-ray.

Summarising the points raised in the new European whitepaper, Phil reaffirmed the importance of taking a risk and fact based approach to determining which technology to invest in: “Every technology advancement helps to build a safer food environment for all, protecting consumers and suppliers. Previously, it might have been harder to justify the cost of having both inspection technologies on a single line. However, given that even the best systems are not infallible, there are certainly occasions where have both metal detection and x-ray could be warranted.”

To assist with decision making, Fortress Technology offers food processors a service that tests products on both a metal detector and an x-ray system. Customers are then presented with detailed reports and analysis to help inform their CapEx decisions.