The optimal process for the conversion of liquid products into bulk materials depends on the desired properties of the final particles, and the specific application. Here, Glatt is well-placed to advise on the pros and cons of each method thanks to its experience and expertise in designing fluid bed systems for individual needs and end products.

The process of drying liquids allows the resulting product to be more easily managed and stored at ambient temperatures. Furthermore, not only is the end product more stable than liquid raw materials, but it also has significantly reduced weight and volume, thus reducing transportation and storage costs.

To dry liquids quickly and effectively, spraying them into a hot air stream (spray drying) is a cost-effective method that has been used for decades to process high-volume bulk products such as milk powder. Spray drying is also ideal for products with a low solids content as relatively high temperatures can be used. Due to the fact that a lot of water evaporates, the cooling effect and the short processing time help reduce heat-related damage. However, the fine particles generated can create dust problems, especially when enzymes or other proteins are involved. As they are often potent allergens and finely distributed as dust, further processing is therefore required.

Targeted solutions for numerous applications

Fluidised bed spray granulation processes take the basic concept of spray drying to a whole new level, with targeted solutions for a range of material systems, applications and market sectors. Compared with spray drying, the fluidised bed process allows the desired product properties, including structure and size, to be adjusted in a targeted manner. This is made possible by combining two process steps: convective drying or solidification and particle formation, with particle sizes from 200 µm to 2 mm easily achievable. By contrast, spray drying only produces particles of about 10 µm – 300 µm in diameter. The dispersed droplet dries during its descent from the spray tower, which means its size is limited by the height of the tower, so significant particle growth can only be achieved with an additional agglomeration step.

Droplet formation and film drying

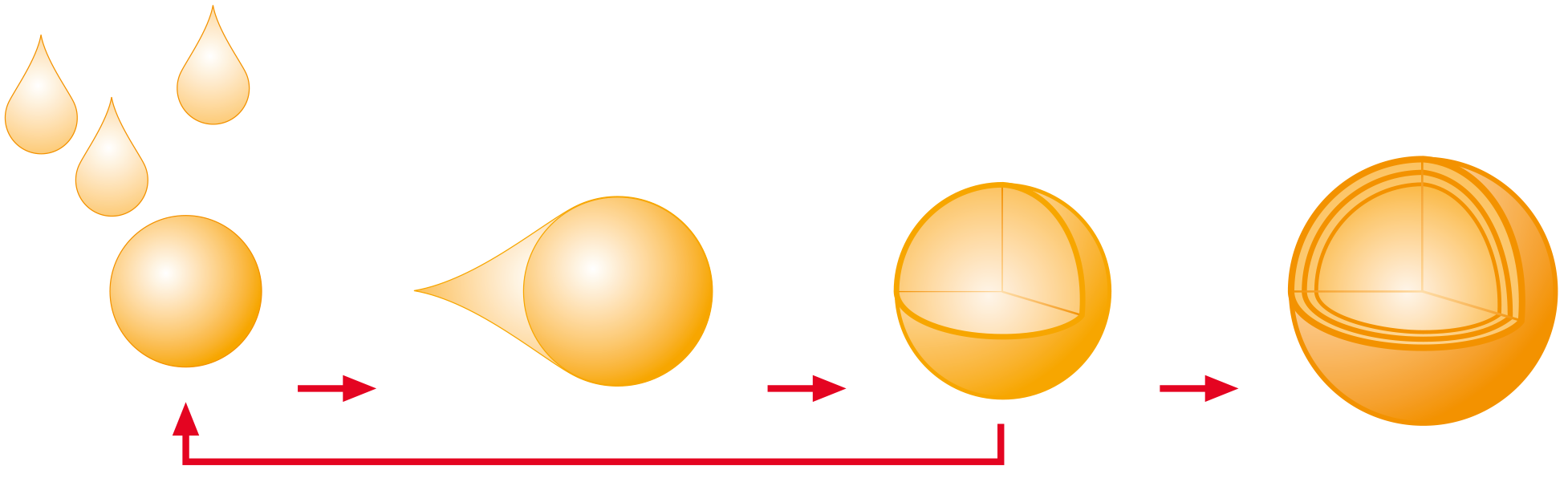

In contrast to spray drying, during which the liquid containing solids is atomised in an empty process chamber, in spray granulation it is dispersed into a bed of fluidised particles. The solvent – usually water or an organic substance – quickly evaporates, so that particle growth occurs by droplet formation and film drying (Fig.1). During this process, known as granulation drying or build-up granulation, new nuclei are continually generated.

They can be produced in two ways: by abrasion and/or the fact that some atomised droplets miss the particles suspended in the fluidised bed and dry directly. Externally, granulation nuclei can be formed from fine particles or crushed granulates derived from the grinding-screen circuit. Here, oversize and undersize particles are separated, crushed by a pin mill and fed back into the process. Both the direct (spray drying) nucleation – the so-called overspray – and the indirect nucleation control the steady growth of the particles during the process, and form the basis for stable and continuous granulation. (Fig.2)

Creation of custom particles

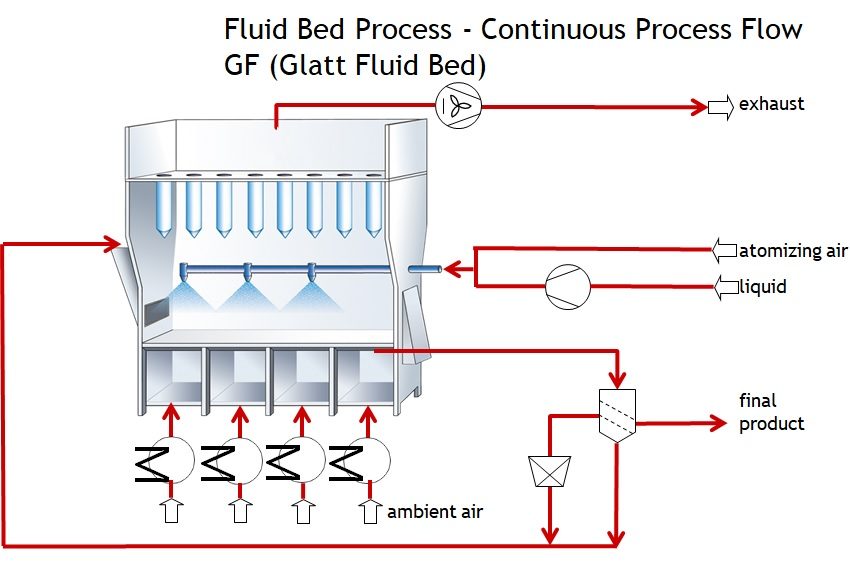

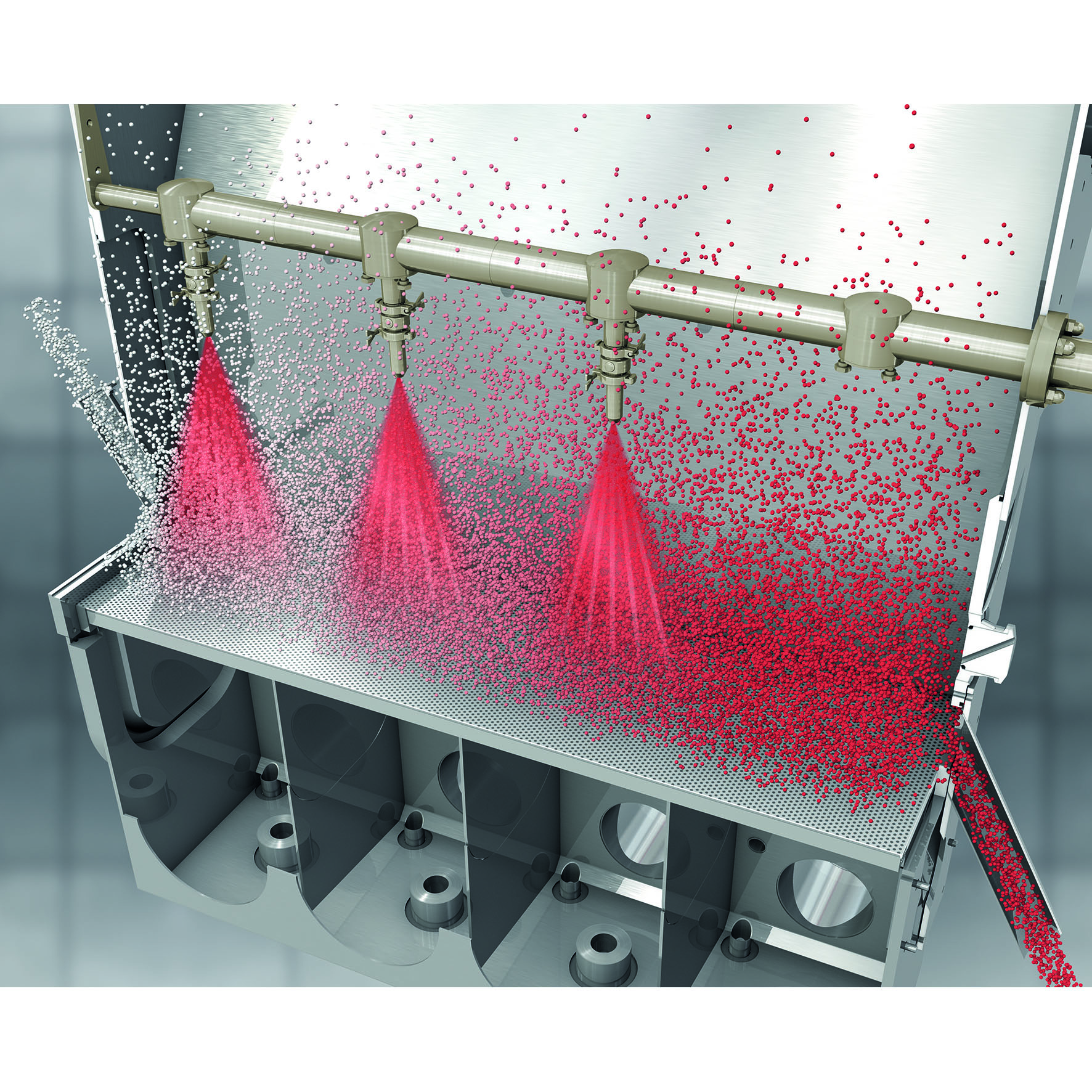

Thanks to their multi-chamber design, continuously operated fluidised bed spray granulation systems (Fig.3) allow for the combination of several process steps. Theoretically, a rectangular fluid bed system can be built to any size, so that different product properties can be set in successive process chambers to create custom particles.

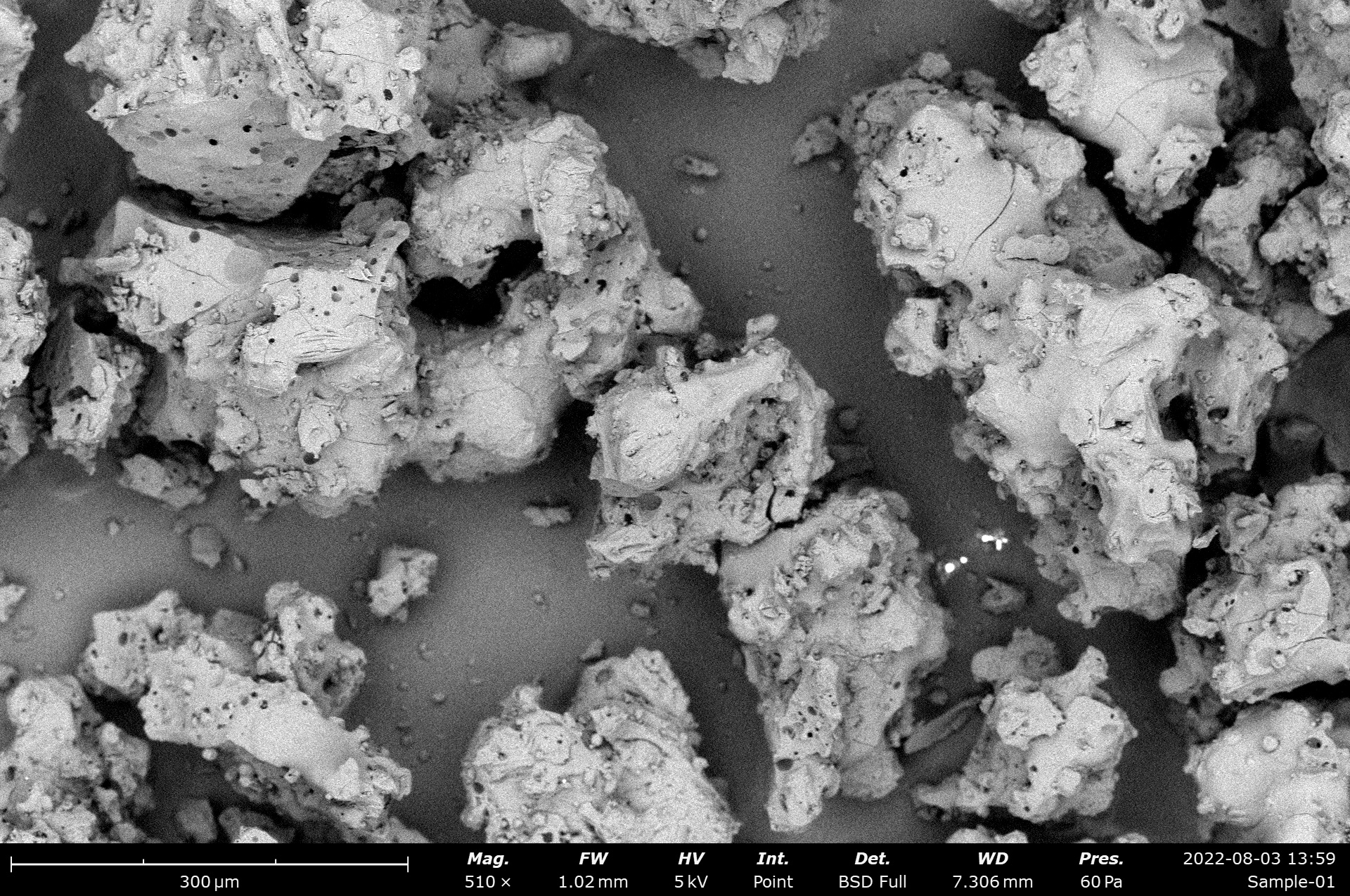

In several projects, Glatt process engineers were able to decrease the particles size significantly and generate soluble, powdery particles from a solution of e.g. hydrolysed proteins by using a fluid bed with an initial spray-drying step. These were then agglomerated and reached a higher density due to collisions and ongoing wetting. Finally, these particles dissolved faster in water as they immerse more quickly than purely spray-dried products. Besides the solubility, this process reduces packaging volumes due to the higher bulk density, which generates savings in storage and transportation – a step further for sustainability. (Fig.4)

In several projects, Glatt process engineers were able to decrease the particles size significantly and generate soluble, powdery particles from a solution of e.g. hydrolysed proteins by using a fluid bed with an initial spray-drying step. These were then agglomerated and reached a higher density due to collisions and ongoing wetting. Finally, these particles dissolved faster in water as they immerse more quickly than purely spray-dried products. Besides the solubility, this process reduces packaging volumes due to the higher bulk density, which generates savings in storage and transportation – a step further for sustainability. (Fig.4)

Closed-circuit environment

Multi-chamber fluidised bed systems can spray from above or below. Intermediate drying and cooling steps are also possible, and subsequent cooling can be done in the same unit. Fluidised bed spray granulation systems that handle organic solvents or oxidation-sensitive products can also be easily integrated into a closed-circuit environment.

A key difference between spray drying and fluidised bed spray granulation is particle size and morphology: in spray drying, particles dry from the outside in; while in fluidised-bed spray granulation, the particles dry from the inside out.

The hot air stream in which the droplets dry creates a hard outer shell, which boosts the concentration of the dissolved component, yet the inner core of the particle remains liquid. As the temperature increases, this moisture evaporates and diffuses, causing hollow spheres. Indentations in the particles occur if the moisture suddenly escapes. Furthermore, depending on the drying speed and concentration of solids in the liquid, the particles might rupture, which makes them unsuitable for encapsulated actives. (Fig.5)

Protecting active components

Spray granulation also produces compact, round spheres with an onion-shaped structure by building up the product layer by layer. This enables flexible and complex product design as particles can be formed from different solid layers, with cores loaded and coated (Fig.6), giving nutraceutical manufacturers the opportunity to create functional products with added value. Furthermore, coating the previously spray granulated particles can be done with the same apparatus to protect the active component or mask unpleasant tastes and smells.

Spray granulates differ from dried products in that particle size, shape and structure can be adjusted according to the desired application. Fluid bed spray granulation is recommended for sensitive nutraceuticals, for example, and for turning emulsions and oils into compact particles. As they have a smaller surface area compared with spray dried products, these nutraceuticals are better protected against oxidation and have a lower drying temperature.

Glatt closely monitors every fluid bed project, from commission through to installation. Beyond the development of customised and functional product solutions, the company also offers project initiation, development and delivery to turnkey factories.

How does the fluidized bed spray granulation process differ from spray drying in terms of adjusting product properties and achieving particle sizes?